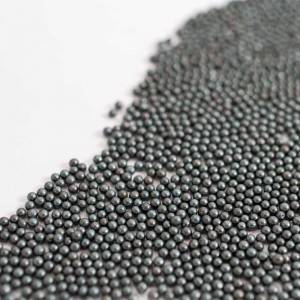

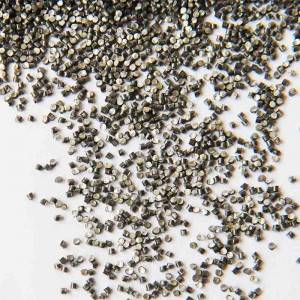

Babban Carbon Rounded Karfe Shot

Samfura/ Girma:S110-S930/Φ0.3mm-2.8mm

Cikakken Bayani:

High carbon karfe harbi, sanya daga musamman karfe, taurare da kuma tempered, da abun ciki a cikin carbon mafi girma fiye da 0.85% ta atomization tsari, mai siffar zobe barbashi, Ya sanya daga narkakkar steel.Fengerda tsananin iko kowane mahada na samar, musamman kula da deoxidation da kuma decarbonization, zafin jiki a cikin quenching tsari, kazalika da kawar da pores da rashin daidaituwa bayan kafa, wanda inganta samfurin zuwa wani sabon matakin.

Maɓalli Maɓalli:

| AIKIN | BAYANI | HANYAR GWADA | |||

| HADIN KASHIN KIMIYYA |

| 0.8-1.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

| Si | 0.4% | Cr | / | ||

| Mn | 0.35-1.2% | Mo | / | ||

| S | ≤0.05% | Ni | / | ||

| KARATUN KARANTA | Homogeneous Martensite ko Bainite | GB/T 19816.5-2005 | |||

| Yawan yawa | ≥7.0*10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| WAJEN WUTA | Ramin iska <10%.Conjoins.Kusurwoyi mai kaifi.Adadin Nakasa <10% | Na gani | |||

| TAURE | HV: 390-530 (HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Matakan Gudanarwa:

Amfani:

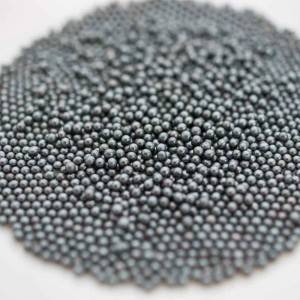

High Carbon Rounded Karfe Shot ta amfani da gargajiya masana'antu dabara, yi amfani da tsãwa tsaftacewa da harbi peening mainly.Cikakken sarrafa zafi jiyya samar da shi da ganiya juriya da juriya ga gajiya.

da kuma gama sassan ƙarfe waɗanda ke buƙatar ƙarin lalacewa da kaddarorin gajiya.Ana cikin haka, harbin ya yi ta jefa bam a bangaren karfe, yana haifar da kananan dimples a saman.

Dimples suna haifar da matsananciyar matsa lamba a saman sashin, yana ƙara juriyar ƙarfe ga fashe, gajiya, da lalata.Ana amfani da leƙen harbe-harbe don mahimman abubuwan sawa masu ƙarfi kamar gears, shafts da fatun ƙarfe don samfuran haɓakar iska.

Aikace-aikace:

Ana amfani da harbin mu na ƙarfe mai ƙarfi a cikin aikace-aikace daban-daban kamar;desanding, descaling, tsaftacewa, harbi peening da dai sauransu .. The centrifugal atomization tsari da biyu zafi magani a Airblast shuke-shuke, kazalika da ci gaba da ingancin iko matakan, tabbatar da harbi ya zama na mafi ingancin.

Surface fashewar tsaftacewa na forgings, heattreated guda, karfe bututu, sassan da karfe Tsarin, surface jiyya kafin zanen, harbi peening na aiki guda.

Tsaftace filaye na faranti na bakin karfe, faranti na bakin karfe, gami da ba na ƙarfe ba, gashin dacromet.