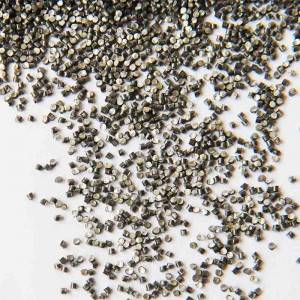

Low Carbon Angular Karfe Grit

Maɓalli Maɓalli:

| AIKIN | BAYANI | HANYAR GWADA | |||

| HADIN KASHIN KIMIYYA | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| KARATUN KARANTA | Homogeneous Martensite ko Bainite | GB/T 19816.5-2005 | |||

| Yawan yawa | ≥7.0-10³kg/m³ (7.0kg/dm³) | GB/T 19816.4-2005 | |||

| WAJEN WUTA | Etched ko angular profile profile, Ramin iska <10%. | Na gani | |||

| TAURE | HV: 390-530 (HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Matakan Gudanarwa:

Scrap → Zaɓi & Yanke → Narke → Gyara (decarbonize) → Atomizing → bushewa → Scalper Screening → Spiralizing&Blowing don cire ramin iska → Na farko quenching → bushewa → Na biyu tempering → sanyaya → Karye → Fine Screening → Packing & Warehousing

KASHIN KARFE KARFE GRANAL KYAUTA

• Yin aiki akan 20% akan babban harbin carbon

• Karancin lalacewa na injuna da kayan aiki saboda mafi girman ɗaukar kuzari a cikin tasirin da ke cikin guda

Barbashi marasa lahani da aka haifar ta hanyar maganin zafi, karaya ko ƙananan fasa

INGANTA MAHALI

• Rage foda

Bainitic microstructure yana ba da garantin cewa ba za su karye ba yayin rayuwa mai amfani

BAYANAR GABA ɗaya

Siffar ƙananan ƙwayar carbon karfe yana kama da mai siffar zobe.Matsakaicin kasancewar elongated, gurɓataccen barbashi tare da pores, slag ko datti yana yiwuwa.

Wannan ba zai shafi aikin harbi ba, ana iya tabbatar da shi ta hanyar auna aikinsa akan na'ura.

TAURE

Microstructure na bainitic yana ba da garantin babban matakin taurin.90% na barbashi suna tsakanin 40 - 50 Rockwell C.

Ƙananan carbon a cikin ma'auni tare da manganese yana ba da garantin rayuwa mai amfani mai tsawo na barbashi, don haka inganta tsabtar sassan, tun da aikin injiniya suna ƙara ƙarfin su.

Ƙarfin fashewar fashewar na'ura yana ɗaukar shi musamman ta sassa, don haka yana rage lalacewa na na'ura.

KARBAR GRANULATION, KYAUTA MAI KYAU

Yin amfani da ƙaramin ƙaramin ƙarfe na carbon yana da iyaka ga injin da ke da injin turbines na 2500 zuwa 3000 RPM da saurin 80 M / S.

Don sabbin kayan aiki waɗanda ke amfani da injin turbin 3600 RPM da saurin 110 M/S, waɗannan buƙatu ne don haɓaka yawan aiki.